-

Plot No. 1197/31, Road No. Nanda Nagar

Near Takshshila High School Indore -

+91 9229182927

[email protected] -

Mon - Sat 10.00 - 06.00

Sunday Closed

Plot No. 1197/31, Road No. Nanda Nagar

Near Takshshila High School Indore

+91 9229182927

[email protected]

Mon - Sat 10.00 - 06.00

Sunday Closed

Ever wonder how individuals receive training on traffic signal installations — or who does the coordination and maintenance of these systems to keep them running smoothly? If you thought the local traffic department, you would only be partially correct. Many municipalities around the country subcontract the installation and maintenance work out to local electrical contractors.

The first traffic signals on record, used in 1868, were red and green gas lamps operated by a police constable. Two semaphore arms extended horizontally and used the words “stop” and “caution” to help direct people, horses, and horse-drawn buggies. The first manually controlled traffic lights were introduced in 1913 — with automated lights making their first appearance in 1920. The installation and maintenance of traffic signal systems have evolved considerably since then.

The Traffic Signals group oversees maintenance, modifications and general repairs of approximately 325 traffic signal devices to provide safe, reliable and efficient operation for roadway users. Police, City staff, citizens, and other public agencies report traffic signal maintenance needs.

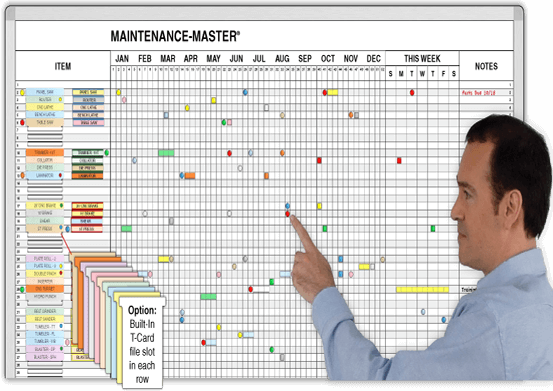

Preventative and corrective maintenance efforts and costs can be related to the quality of design practices, construction methods, and the use of quality parts. Effective preventative maintenance practices can decrease the cost of operating and maintaining a traffic signal infrastructure - resulting in a safe and reliable physical plant.

Maintenance of Signal Control BoxA large part of maintenance work is inspecting or replacement of traffic control equipment before it fails, including: semi-annual inspections and testing of control equipment, intersection hardware, vehicle detector loops, pedestrian pushbuttons, poles, signs, signal heads, and mounting hardware; annual re-lamping of light bulbs for walk and yellow signal lenses, and cleaning of all signal lenses; and re-lamping every 8-10 years of all Red, Yellow, Green, Walk/Don’t Walk, left/through arrow, and countdown timers, which are LED (Light Emitting Diodes) type lamps.

Corrective maintenance is performed on an hierarchical priority basis considering the seriousness of reported problems, current work tasks and available equipment and manpower. Many reported problems can be verified by traffic signal monitoring functions available via the central traffic control system. Problems generally responded to during regular business hours are: light bulb outages, signal head alignment adjustments, vehicle detector tuning/repair, pedestrian pushbutton repair, communications network troubleshooting and repair, motor vehicle accident damage repair, minor physical plant upgrading, ontroller/cabinet and communications equipment troubleshooting and repair, repair/replacement of signs and damaged signal equipment and signal timing adjustments.

Traffic signal modifications or upgrading result from additional control needs, advances in technology, infrastructure renewal or roadway geometry changes. Examples are: development of new or remodelled intersections in conjunction with adjacent land use development, installation of communications cable and modem equipment for communications between intersections and the Central Traffic Control computers, pedestrian push button upgrades with a more reliable and user friendly design, replacement and relocation of degraded traffic signal poles, and equipment, implementation of advanced vehicle detection, installation of left turn signals, and installation of audible/accessible devices.

Copyright © Electroads 2018. All rights reserved.|Designed And Developed (P) Ltd Myinfoline.com